TEL:+86 0536-6162866+86 187-6464-2379

ADD:No.19, Shunde Road, Zhucheng City, Shandong, China

WEB:happymail.net.cn

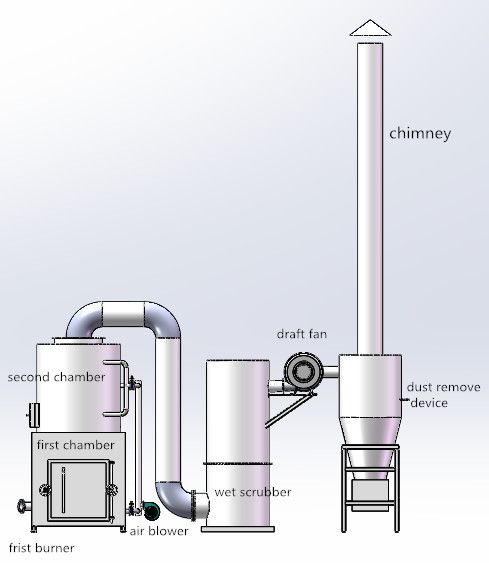

smokeless waste Incinerator with wet scrubber gas treatment system

-

MS:Katherine Wong

+86 187-6464-2379

-

TEL:+86 0536 6162866

MAIL:sales@cntianlang.com

-

smokeless waste Incinerator with wet scrubber gas treatment system

Product Description

The incinerator pyrolysis generally uses a fixed hearth incinerator, which mainly includes a furnace body, a steel frame, refractory materials, and thermal insulation materials.

Waste, combustion air and auxiliary fuel undergo complex chemical reactions in the furnace to completely oxidize and decompose harmful substances in the waste. The structure and size of the furnace and the furnace determine the treatment capacity of the incinerator and the decomposition and removal of harmful substances in the waste. rate. The furnace body is provided with a burner, and the furnace is heated to a certain temperature by a burner, and then the waste is ignited. The secondary combustion chamber is provided with a burner for burning the incompletely combusted organic gas in the flue gas, and a unique air supply device for supplementing the oxygen required for the waste combustion, and adjusting the air in the incinerator The amount is used to control the pyrolysis and combustion temperature in the furnace.

Product Application

1.Medical waste: syringes, neddles, gloves, straps, gauze, blood vessels, organs and other infectious waste.

2. Industrial waste (polymer waste): Plastic PE, PU, rubber (tire), Styrofoam, PET bottle, fiber, foam, cloth, bags, resin, acrylic, leather, Wood flour, urea powder, melon cloth, tapes, paints, polymers and so on.

3. General garbage: cardboard, paper scraps, sawdust, leaves and so on.

4. Special waste: waste oil, waste solvents, oil sludge, ash dust, iron paint, mold filter residue and so on.

5.Animal carcass cremation.

Advantages of incinerator

1. Environment friendly,Dual chamber design, no smoke, no smell, no pollution.

2. The highest temperature can reach 1100-1300 degrees Celsius, which can achieve the effect of sterilization and disinfection

3. long service time.Material of construction-Heavy duty steel. Insulated and refractory lined chambers.

4. be portable and cover a small area.

5. Low running & maintenance cost.

incinerator structure:

1. Furnace body:

1) The furnace body combustion chamber adopts horizontal grate furnace, which belongs to the third generation incinerator, which is connected with the improved inner wall seamless air guiding and blowing system. The mixing degree is particularly ideal, saving fuel, no secondary pollution, and more than the general furnace. Durable and long lasting.

2) The furnace body adopts refractory type. In addition to protecting the outside of the furnace, it can be kept in a constant temperature state, and there will be no abnormal high temperature phenomenon, which can reduce the generation of NOx and avoid secondary pollution (which cannot be restrained by the general refractory brick furnace) .

The temperature of the jacket refractory of the furnace body is about 60-80°C, which is the purpose of recycling energy and comprehensive utilization, and has good economic benefits.

4) The furnace body combustion chamber is designed according to the principle of incineration.

5) The furnace body adopts a uniform uniform high-pressure modified inner wall non-weld air guiding system. The air nozzle is not easy to be damaged in the jacket, and can be warmed into the furnace air by the jacket refractory material to save fuel and strong air speed. 30-100M/S, the burning speed is 5-10 times higher than the general increase, which can make the waste have enough air to achieve the complete combustion effect.

6) A dust-cleaning door is arranged at the bottom of the furnace body to facilitate cleaning of the ash.

7) The furnace center temperature is maintained at around 850~1100 °C for incineration. The organic matter in the waste can be fully oxidized, and the incineration efficiency is 99.99%. The stable gas produced has the effect of completely burning without odor, odor, and smoke.

8) The furnace has a large internal volume and the furnace load is 400,000 kcal/* (M3*H). It is enough to cope with the mixing of various polymer waste materials, and it has a wide range of adaptability and stability.

2. Air blower:

The fan adopts high-pressure centrifugal fan, which is specially designed and fixed-point production to ensure the flue gas in the purification system.

Medium and negative pressure operation.

3. Chimney:

It is 6 meters above the ground and is fixed by a rain cap.

4. Electrical control system:

It includes an electronic performance monitoring and logging system. The system be capable of monitoring and logging chamber temperatures at regular intervals (not less than once per minute, with the capacity to vary the logging frequency). The system include the capacity to download the performance data by USB connection.

Incinerator device power indicator, switch, temperature and pressure display instrument;

The temperature be determined against the inside wall of the combustion chambers. An audible and alarm shall be installed to warn the operator when the secondary temperature drops to below the required temperature.

There is interlock control system; And The overload protection device protects the motor from overload.

5. wet scrubbers:

Use water or lime water (better effect) to spray the flue gas to remove large particles of floating matter and impurities in the flue gas, which can reduce the working pressure of the subsequent equipment and prolong the service life of activated carbon and bag dust removal.

6. Cyclone dust collector:

Working principle: After the hazardous waste is incinerated, the gas generates dust and enters the cyclone dust collector under the action of the induced draft fan. The cyclone dust collector separates the particulate dust from the airflow by the principle of centrifugal drop. The upper part is conical. When the dust-containing gas enters from the spiral of the intake pipe on the upper side of the cylinder, it encounters a reverse spiral wind, and the separated dust is from the dust. The top of the cylinder is discharged and the dust particles fall into the dust collector. The function of the dust collection system is to collect the dust particles in the flue gas generated by the incineration garbage, which is convenient for cleaning and ensures the working efficiency of the subsequent equipment.

V. Process Technology

Before the operator starts the pilot fan to purge the residual combustible gas before starting the furnace, other motor equipment can be operated.

The garbage is put into the furnace, and after the ignition, the blower is started, and the waste is burned in the furnace body by its own calorific value. The garbage is fully burned under the action of high pressure combustion air. The high temperature of 650-1000 °C in the furnace, the waste is completely burned and decomposed.

The secondary combustion chamber is actually a gas burning furnace, and the unburned gas in the furnace body enters the secondary combustion furnace and is fully burned in a high temperature environment. According to the "three T" principle design, the furnace temperature is controlled to ≥1100 °C, and the residence time in the high temperature zone is ≥2 seconds, so that the harmful substances are completely decomposed.

The high-temperature flue gas generated by incineration enters water cooling device, the temperature will be lower, then was romoved particles by wet scrubber, The spray can cool the temperature and remove the large particles of impurities in the flue gas. After spraying, it enters the cyclone dust collector to remove the remaining large amount of dust in the flue gas, ensuring the remaining dust. The normal operation of the subsequent equipment, the removal efficiency of large particles of dust above 100um is more than 90%.

Finally,it is discharged by the chimney.

hazardous waste will produce dioxins at temperatures below 400 °, and our company will incinerate the waste when the design temperature of the combustion chamber reaches 600 ° or higher, and the second combustion chamber will incinerate the exhaust gas by 1000 °, greatly reducing The dioxin index, coupled with the subsequent treatment of the exhaust equipment and the residual PCDDS/PCDFS (dioxin) in the exhaust gas of the activated carbon device can solve the problem of dioxin production.

The flue gas finally reaches the effect of “non-toxic, harmless and odorless” and is discharged through the chimney.

FAQ:

Q: How to buy your idea products?

A: You can provide us the waste kind and waste quantity(connect us for more details). we will recommand you the suitable model incinerator.

Q: How to pay?

A: TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

Q: What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 3 to 4 weeks.

Q: How to pack the products?

A: We use standard package.

Q: How to install after the equipments arriving destination?

A: We will provide detailed illustrations to you. And we will send a technicians to guide for installation and debugging. after debugging equipment, he will teach your workers how to use it and how to maintain it.

Q: How about the warranty?

A: If there is any malfunction of the equipment during the warranty period, our company promises to propose a solution within 24 hours. If it is caused by non-human causes, our company provides repairs free of charge and guarantees that the equipment is running well again.

Q: What's the certification do you have?

A: We have CE, ISO9001, OHSAS18001, ISO14001 Certifications

contact me:

Katherine Wong

email:tianlang01@cntianlang.com

+86187 6464 2379(Tel,whatsapp,skype,Wechat is same ID)

Tel

Tel Home

Home Products

Products